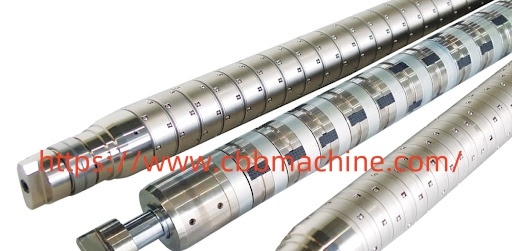

In the complex field of web handling and material processing, the Differential Air Shaft has emerged as an essential solution for managing multiple rolls with varying tension requirements. This advanced component provides the precision needed when different materials are wound together, ensuring each roll is maintained at the correct tension to avoid slippage, stretching, or uneven edges.

The core functionality of this system lies in its ability to adjust tension automatically between multiple rolls. Unlike traditional shafts that apply uniform force across all materials, this technology introduces a differential mechanism. It enables independent adjustment of each roll, which significantly enhances performance in industries where consistency and quality are non-negotiable.

Applications of this device can be found across packaging, printing, textiles, and other industries where multiple rolls must be wound or unwound simultaneously. By stabilizing the winding process, it not only reduces defects but also supports efficient use of raw materials. This translates into fewer production errors, reduced waste, and improved throughput.

Another critical advantage is its versatility. The shaft is adaptable to a wide range of materials, whether thin films, foils, papers, or textiles. Each type of material responds differently to stress, making it vital to maintain accurate tension control. By offering this adaptability, the system ensures that manufacturers can process diverse product lines without constantly changing equipment.

Durability is also a key factor. Built for industrial use, these shafts are engineered with strong materials that withstand continuous operation. This resilience minimizes maintenance costs and allows businesses to rely on the equipment for extended service life. With fewer interruptions, companies can maintain consistent productivity and meet delivery timelines more reliably.

From a cost-efficiency perspective, the benefits are clear. By reducing waste, lowering downtime, and improving material usage, businesses can achieve long-term savings. Moreover, the precision provided by this component helps enhance the overall quality of finished products, which is crucial for customer satisfaction and brand reputation.

Beyond efficiency and durability, this system also promotes workplace safety. Controlled tension prevents unexpected roll behavior, reducing risks for operators during machine operation. Combining safety with productivity makes it an important part of modern industrial solutions.

In summary, this technology represents an innovative step forward in web handling. By enabling independent tension control, supporting multiple material types, and enhancing safety, it provides both immediate and long-term value to industries worldwide.

For more detailed insights, you can visit https://www.cbbmachine.com/news/industry-news/differential-air-shafts-key-components-applications-benefits-and-more.html