In industries where extreme conditions demand unwavering performance, selecting materials that combine strength with intricate shaping becomes essential for innovation. Zhufa Precision Ceramics stands at the forefront of this domain, offering components engineered to withstand intense heat, corrosion, and wear while maintaining exact tolerances. These advanced creations support applications ranging from sophisticated machinery to delicate electronic systems, enabling designers to push boundaries without compromise. Crafted through meticulous processes, they deliver reliability that enhances operational longevity and efficiency across diverse fields.

Material selection influences outcomes profoundly. Engineers often seek substances capable of enduring harsh environments without degrading. Such ceramics excel in thermal stability, resisting rapid temperature shifts that would damage conventional options. Their inherent hardness protects against abrasion, making them ideal for parts exposed to constant friction. Lightweight properties contribute to overall system optimization, reducing energy requirements in moving assemblies. Smooth surfaces minimize resistance, facilitating fluid or gas flow in critical pathways.

As focus on sustainability grows, choosing durable elements gains prominence. These components require less frequent replacement, aligning with resource-conscious approaches. Manufacturers incorporate them into equipment designed for extended service life, supporting broader conservation goals. Custom shapes allow seamless integration into existing frameworks, avoiding extensive redesigns. This adaptability empowers teams to refine products for specific demands, fostering creativity in development stages.

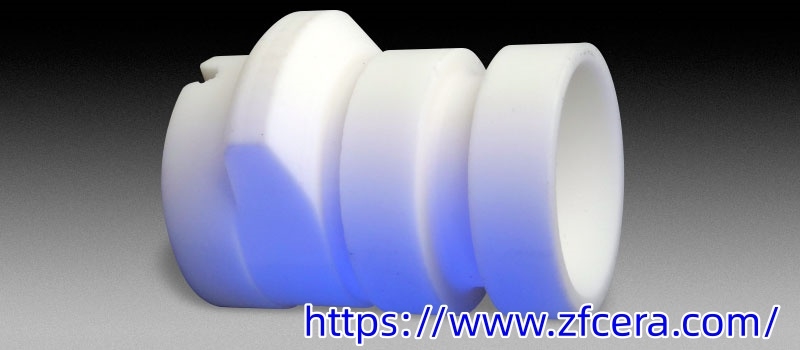

Aesthetic qualities complement functional excellence. Polished finishes provide clean appearances suitable for visible applications, while color consistency ensures uniform integration. Tight dimensional control guarantees precise fitting, eliminating gaps or misalignments that could impair performance. Maintenance involves simple cleaning routines, as non-porous structures resist contaminant buildup.

Communities dedicated to technological progress frequently discuss ways to elevate designs. Aerospace enthusiasts appreciate how lightweight strength contributes to fuel efficiency, whereas medical device creators value biocompatibility alongside robustness. Automotive innovators employ them in high-temperature zones, and energy sector professionals rely on insulation properties for safe operations. These shared insights highlight transformative potential, encouraging exploration of specialized providers.

Masterful fabrication techniques underpin superior outcomes. Experts employ advanced forming methods to achieve complex geometries previously unattainable. Controlled sintering ensures dense microstructures free of weaknesses, enhancing mechanical integrity. Surface treatments further improve resistance to environmental challenges, extending usability in demanding settings.

Educational contexts demonstrate material properties vividly, engaging learners through tangible examples. In research laboratories, precise components enable groundbreaking experiments by withstanding reactive substances. Consumer electronics benefit from thermal management capabilities, keeping devices cool during intensive use.

Pursuing excellence in challenging applications often leads to brands embodying dedication. ZHUFACERA represents such commitment, delivering solutions that meet rigorous standards effectively. Delving into comprehensive resources reveals tailored offerings that align with unique project needs.

Navigating material choices uncovers abundant possibilities, yet prioritizing advanced ceramics yields remarkable advancements. Recommendations direct toward platforms providing detailed guidance and selections.

To explore these exceptional material solutions and discover components suited to your innovative projects, visit https://www.zfcera.com/product/